Elon Musk recently tweeted that “humans are underrated”, and that heavy automation didn't have the results he expected in Tesla’s gigafactory. Isn’t this a great example of what’s wrong with digital transformation and smart factories?

Yes, excessive automation at Tesla was a mistake. To be precise, my mistake. Humans are underrated.

— Elon Musk (@elonmusk) April 13, 2018

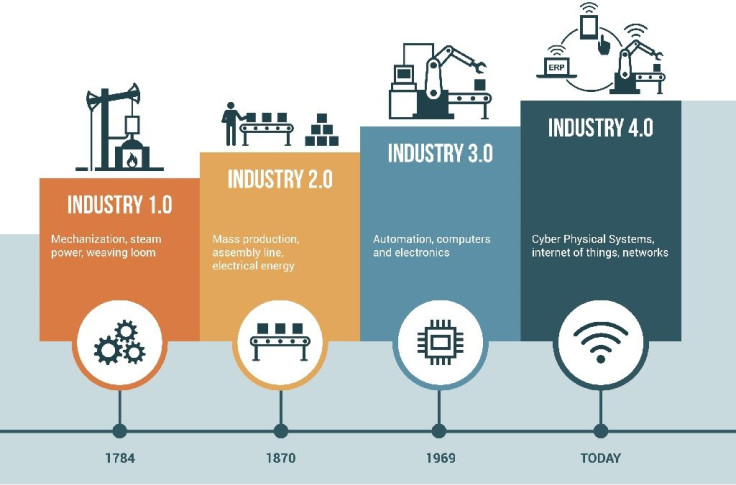

Everyone is talking about industry 4.0, the fourth industrial revolution, and how it’s going to change the industrial word. Everyone believes it’s all about robotic, full house automation, and no more human beings in factories. Well, in my opinion, this image of the future of manufacturing is wrong!

Let’s get back to basics. What exactly is Industry 4.0?

McKinsey defines Industry 4.0 as “the next phase in the digitalization of the manufacturing sector”.

Image Credit: International Business Times

Indeed, it is the label given (by Germany) to the gradual combination of traditional manufacturing and industrial practices with the increasingly technological world around us. Several disruptive technologies are at the center of these changes: Big data, Internet of Things, Robotics, Artificial Intelligence, etc.

Today, a lot of industrial companies have tested these concepts and have seen some significant changes and improvement. In India, for example, equipment effectiveness reportedly increased by 18%, while a Michigan plant cut downtime by as much as 20% by applying IoT sensors to monitor wear.

Another example is IBM's Maximo Asset Management, which is allowing users to sense, communicate with, and diagnose problems on connected devices and machinery in the plant, the company says the data gathered from workflow processes, throughput, and yield can reduce defect rates by up to 48%.

Industry 4.0 is definitely NOT about to change the manufacturing industry - it already has! However, everything is not as good as it seems and some issues and concerns are starting to pop up…

Digital Transformation

Ok. Let’s say that we understand that the fourth industrial revolution is here. What’s the issue, you may ask? We actually seem to forget that it’s here to help us, humans, have a better life, not replace us and make us miserable!

Let’s start by listing some facts:

-

Buzz Words: Industry 4.0, Advanced Manufacturing, etc. these are some very hyped buzz words! Why? Because everybody is talking about them and nobody knows what they actually mean! Understanding these concept and the technologies behind them is the first step to succeed in their implementation.

-

Heavy Investment: In the past, implementation of technologies required a lot of money but today it is more affordable. The technology is becoming cheaper, which means you can win a lot without investing a lot.

-

Latest fancy robots: You need the most qualified robots to fulfill your strategic objectives, but this doesn’t mean getting the most expensive or cutting-edge equipment. Don’t forget that technology is here to solve problems for us, not the other way around!

-

Is a connected factory the key?: Yes, you need to be able to collect data. However, the real challenge is in analyzing it and getting something out of it. It’s more about reading the right data than about connecting everything.

-

No more employees?: While some jobs are certainly going to disappear, other jobs are actually going to be created as a result. You don’t have to fire your employees as you can retrain them for new tasks that automatisation will require. Also, if you have no more humans in the factory, who will celebrate the success of the factory?

The biggest issue of Industry 4.0 is that we seem to forget that its main purpose is to find solutions to manufacturing issues and get it to the next level so it has a positive impact on the industry as well as local economies.

[Industry 4.0] is augmenting, not automating our people" - Cliff Justice, Partner at KPMG

Humans - Are they Underrated in Factories?

The point that I’m trying to make is that humans should be part of the ongoing industrial revolution. To succeed, manufacturers will need the commitment and talents of their employees!

It’s actually false to think that Industry 4.0 means zero manpower, and in fact there is actually a shortage of manpower. However, it’s important to recognize that individuals may not perform the same duties they had before.

According to Manufacturing Global, “an estimated 186,000 new engineers will be needed each year until 2024, yet there’s a shortfall of 20,000 graduates annually.” Actually, robots do not steal jobs, they do the ones that people do not want to do anymore, while people’s jobs are shifting to jobs with more added value.

Here is an example of how digital transformation is creating more jobs than destroying in Germany, how robots are helping humans on the basic and difficult tasks, improving the workers security and why after converting to full house automation, Mercedes decided to go back to basics by replacing its robots with humans. Lastly, an interesting read on this subject is the KPMG report on Industry 4.0 is all about people.

It’s important to keep in mind that all industrial revolutions have led to changes in the kinds of jobs people perform. However, people always found a way to work.

Before the first industrial revolution 40% of the population was agricultural workers; today it is only 2% and yet there is still plenty of work available.

What Can We Expect in the Future?

Industry 4.0 is a movement that brings together many concepts. Knowing what it is, understanding the technologies behind it, and assessing what kind of improvement they can actually bring is the most complicated task for a manufacturer.

To conclude, I would ask you not to believe everything that is said about Industry 4.0 and advanced manufacturing (yet another buzzword) and start implementing projects step by step. Remember, when it comes to optimizing your company for Industry 4.0, don’t try to change the entire organization at once, but focus first on projects that will involve and engage your employees. And whatever your thoughts on this emerging trend, don’t forget that Industry 4.0 is a matter of life or death for manufacturing companies.

And with that, I leave you with some wise words from John Hitch’s article, “Adopt or Die: AI Leaves Manufacturing No Choice”:

The dawn is just breaking in this fourth industrial revolution. Brand new dreams and ambitions crown the horizon: skylines of smart factories, smart cities, smart Martian colonies. It feels like the future of old, in fact. And where we're going, we'll still need roads, but not drivers.

This guest post was written by Amira Boutouchent (CEO and Co-Founder of BRIDGR and Graduate of the Montreal Founder Institute). Learn how BRIDGR is helping manufacturers transition to Industry 4.0.